The measuring method, which exactly measured ?

Quantitative regulation

of hydrocarbons in water-surface-air

Oil consists of a mixture

of chemical substances, particularly of hydrocarbons. In order to receive from it

consumptionable products, essentially four processing levels are necessary:

Distillation, the separation of the crude oil according to more easily and more

heavily simmering portions (e.g. gasolines, petroleum etc..)

Converting (Cracken) the distillation residues into additional gasolines and

central distillates cleaning (refine) the crude oil products improving (reform)

the gasoline quality.

In all processing steps and later in application, the consumption of the products, hydrocarbons can arrive into the environment.

Hydrocarbons cannot be measured directly, E.G. by truebungsmessung.

It is common to all measuring methods that before the analysis an extraction with organic solvents must be accomplished, since a direct regulation of oil is not possible in water with low concentrations. Water exhibits a strong absorption band likewise in the IR spectrum.

With the quantitative IR analysis the intensity is measured after the absorption, whereby either the maximum absorption or extinction of a gang or however the integrals extinction within a certain wavelength or wave number range are seized.

From the extinction

the concentration can be computed, if the molecular extinktionskoeffizient admits is. Since

this is dependent on the special chemical structure of the molecule, he must be determined

empirically.

The evaluation is very simple with knowledge of the molecular extinktionskoeffizienten,

i.e. if well-known hydrocarbons are to be quantitatively seized.

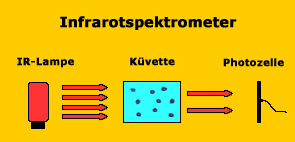

The measurement principle lies in the absorption of infrared light by IR-ACTIVE molecules. The more these molecules are present, the more lights one swallows.

IR active molecules are to be found in nearly all organic compounds, the-half a

infrarot-Spektrometer (dispersive Infrarotanalyse), also in physical chemistry,

in biology and physics are used. By the multiplicity of applications and the

associated preparation times as well as the composition of application-oriented

accessories, it empfielt, so far it is itself possible itself only on certain

ranges to concentrating. NDIR (non-dispersive infrared analysis)

Source of infrared

Optical system

Detector

The same principle we

use with our measuring instruments, the difference exist only in the fact that we

concentrate on a certain range. Therefore the expenditure is many smaller to the

measuring procedure, because we before know which we search. In addition we can

automate this procedure and exclude the errors particularly in the sample preparation.

But we developed a certain analysis unit.

We call it also optical bench.

By this principle the possibility exists to select also different ranges and to

furnish the optical bank accordingly.

In the analysis unit the jet sent by the IR emitter is

bundled after passage by the cuvette and given on a Chopperrad (light chopper wheel).

The rotary Chopperwheel equipped with 2 interference filters interrupts cyclically

the path of rays and produces a signal sequence at the detector, consisting of the

trigger -, reference and measuring signal.

The interference filter for the measuring signal

lies in the gang range of 2780 - 3125 cm-1 (3,2 - 3,6 Ám). The reference

filter is in such a way selected that no absorption arises

by the interesting hydrocarbons.

The hydrocarbon concentration appropriate

absorption of the IR radiation into a intensity-proportional tension one

converts and to the announcement one brings.

The flow control and the evaluation of the measuring signal take place in all measuring

instruments automatically via a microprocessor.

All measured values of the OMS-Systems are identical to the IR spectrometers (dispersive Infrarotanalyse), since the same basis exists here. Over within the adjusted wavelengths determined gangs to select an appropriate oil of kind of condition can be used for calibration. We recommend to seize the oil of kind of condition Squalan around the entire range.

The devices are not adjusted to a certain

solvent, it can each suitable solvent be used.